This article will give you general ideas of how snowboards are constructed and what they are made of.

Although every snowboard manufacturer has their own special trick when it comes to making their Snowboards, this section will discuss the basic formula on How to Make a Snowboard.

Snowboard Construction

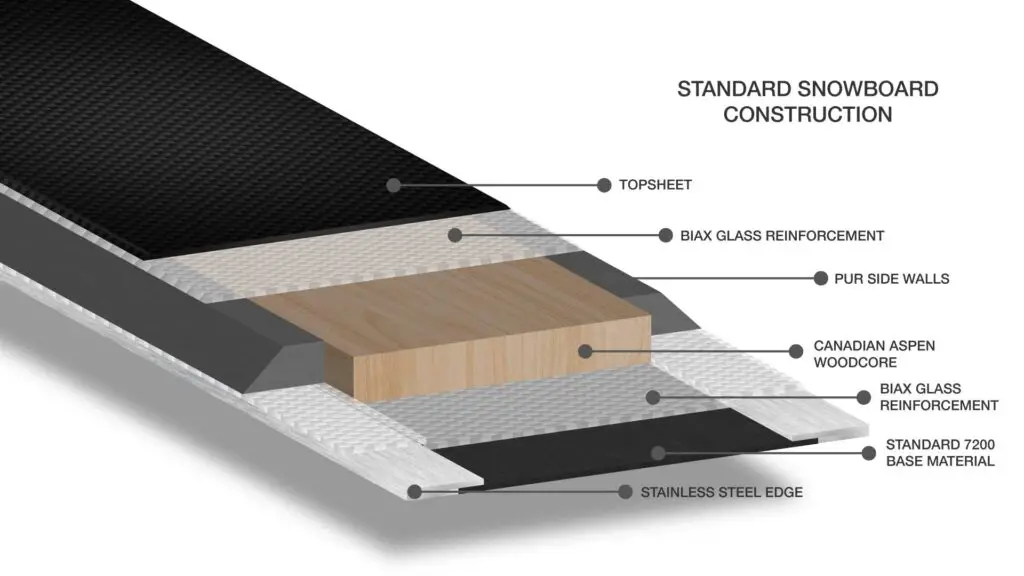

There are some Basic Components that go into the Construction of every Snowboard. Each snowboard has a base, an outer edge, a core, and a topsheet. A good quality snowboard will be constructed like a Ski – it has metal edges and a P-tex base. There are generally Two Types of snowboard Construction: the Capped Snowboards and the Traditional Sandwich Construction.

In Capped Snowboards, the topsheet (outer skin) is pinched over the sides of the snowboard meeting the steel edge. On the other hand, the topsheet on Traditional Sandwich Construction is flat, with the armor plating on the sides provided by separate sidewalls.

Each type of snowboard is similarly constructed with the exception of some tooling modifications. Some designers say that Cap Construction enhances edge hold on hard snow and generally improves board responsiveness.

Others claim that caps are harder to repair if you damage the sidewall. Both types have their merits, keep in mind though that what really matters is the materials under the skin.

What’s in a Board?

The eight main materials in a snowboard are the:

- Topsheet with printed graphic

- Fiberglass or epoxy

- Wood or foam core

- Steel inserts

- Plastic base, (p-tex)

- Metal edges

- Resin System (glue)

- Rubber Foil

Carbon fiber can be added along with other performance-enhancing materials.

Layers of a Snowboard

A snowboard is similar to a sandwich that is made up of many layers. What follows are the components of a snowboard from top to bottom:

The top layer of a snowboard is a protective plastic layer called a “topsheet.” The topsheet does not only protect the insides of the snowboard from damage and exposure to ultra-violet rays, but it also provides a good surface for graphics.

Although the material used for the topsheet can vary, there are basically two types of topsheets – glossy and matte. Glossy topsheets usually come with sublimated graphics. On the other hand, matte topsheets, in general, have screened-on graphics.

Inside the topsheet is a layer of “fiberglass”. This fiberglass lies on top of the core.

The Snowboard’s “core”, which lies beneath the fiberglass, is what the rest of the board is wrapped around with. The core makes up most of the thickness of the Snowboard.

This is usually made of wood foam, honeycomb panels, or a combination of wood and other composite materials, with sets of metal inserts needed to mount bindings.

Cores made from honeycomb are lightweight and are surprisingly strong. With a wood core, you can be assured of a smooth response and lively flex from the board. A foam core, in contrast, can sometimes lose its flex.

Next is another layer of fiberglass, “fiberglass reinforced plastic” in particular. This provides stiffness and strength to the Snowboard.

Following the fiberglass are steel edges. These edges surround the P-tex of the Snowboard, allowing the board to dig into the snow while turning. There are actually Two Kinds of Edges: partial steel edges that run only along the sides of the board, ending at the nose and tail, and edges that wrap all the way around both ends of the board.

On the bottom is a layer of ultra-high molecular weight polyethylene material commonly called “P-Tex.” This is a dense, abrasion-resistant plastic with low friction properties which provides the slippery surface that makes the snowboard slide on the snow surface. To keep your snowboard running fast throughout the winter, you need to add wax to this base layer.

There are basically three different types of snowboard bases – extruded, sintered, and graphite. Extruded bases are long-lasting and easy to repair. However, they are the slowest type of base, and they hold less wax than the other types of bases.

A sintered base is superior to the extruded base since it’s more durable, faster, and can hold wax better. Then again, it’s more expensive and difficult to repair. The graphite base, on the other hand, is the fastest type of snowboard base and has a higher capacity to hold Wax.

This type of snowboard base is always deep black and is mostly found on fast racing boards.

If you’re looking for high performance, opt for a snowboard with a sintered base. Then again, if you’re on a tight budget, an extruded model will do.